Starting in the summer of 2026, Ocean Berlin, a new and innovative underwater world with an impressive aquarium will open in Berlin-Lichtenberg.

Beautiful cost- and environmental saving project underway at our client Royal Burgers' Zoo & Safari Meeting Centre.

On 21-5-1954 Arnold van den Born went to the chamber of commerce to register ARBO special pumps industry.

ARBO strongly supports the vision of a circular economy and the strive for zero waste and increased material efficiency as well as increased energy efficiency.

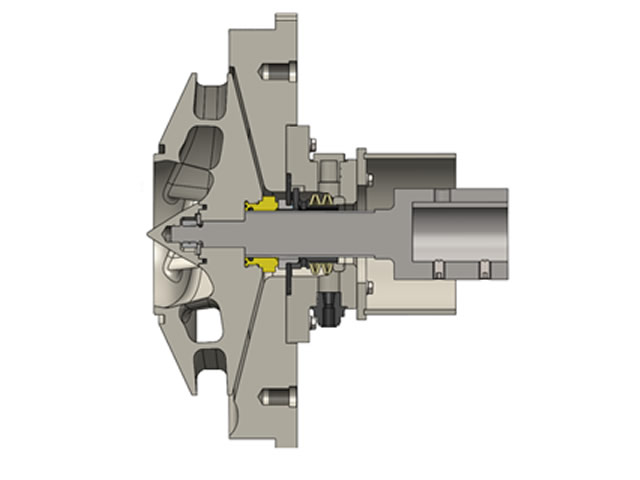

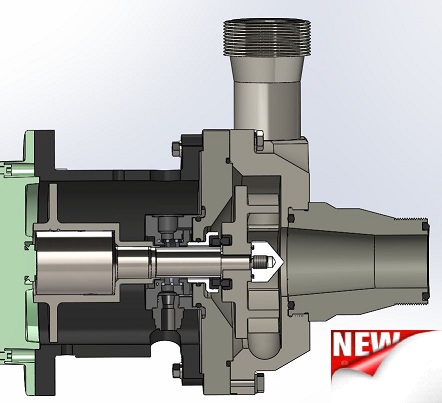

Over the past years our mechanical seal materials evaluated to practically wear free.

John Wasser joined ARBO July 2017.John Wasser joined ARBO July 2017.He has a longer experience in technical sales of many kinds of industrial pumps and worked with several well known pump import and trading companies.

Since May 2018 our quality system has been approved according to the latest standard ISO 9001-2015.

During the year of 2018 our 2500 m2 factory roof has been fully upgraded with high isolation panels and solar energy.

The pumps from this series consist of plastic only.