Centrifugal pumps with mechanical seal

Chemical centrifugal pump

Characteristics chemical centrifugal pump

Check out the advantages of a chemical centrifugal pump in comparisson to a regular pump.

- For all applications where metal pumps suffer from corrosion.

- Interchangeable with metal pumps thanks to normalized connections.

- Machined completely from solid blocks of plastic.

- No metal parts in the liquid – extremely corrosion resistant.

- No injection molding or welding involved – no chemical cracking!

- The highest chemical resistance.

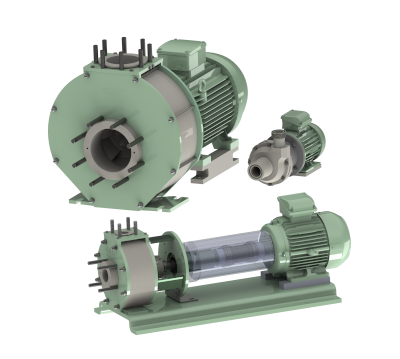

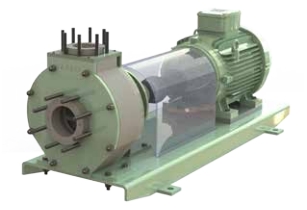

- Close (KR) and long (TK) coupled configurations.

- Horizontal or vertical mounting.

- Special configurations for abrasive liquids.

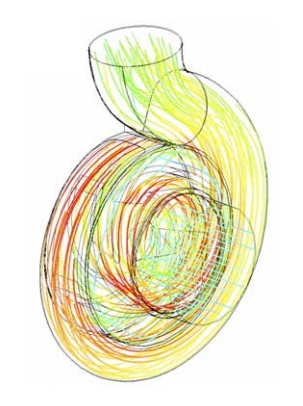

- For plastic pumps unique new hydraulic

- Flow rates (Q) up to 500 m³/h

- Flow rates (H) up to 90 m

As Arbo Pumps we are known as the chemical centrifugal pump manufacturer from the Netherlands.

Download

ARBO PG 1.0 EN.pdf

ARBO PG 1.0 EN.pdf

PRODUCT RANGE CHEMICAL CENTRIFUGAL PUMP

CHARACTERISTICS CHEMICAL CENTRIFUGAL PUMP

|

IMPELLERThis series of centrifugal pumpss is equipped with a newly designed hiEff impeller with pressure-release. It is fixed onto the shaft independently from the direction of rotation. These impellers are particularly suitable for the transport or circulation of (high viscosity) liquids, with maximum efficiency. Solid particles up to Ø 3mm may pass through the centrifugal pump without damage.

|

|

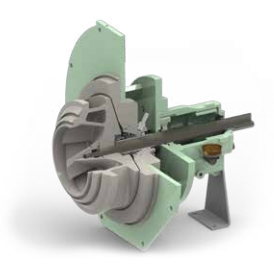

CONSTRUCTIONAll parts that come in contact with the liquid are machined from solid blocks of plastic. Thanks to a special production method and the lack of welds, there is no risk for chemical cracking, a major advantage compared to injection molded centrifugal pumps. PP is the standard material and covers a wide range of duties. For highly abrasive liquids (high percentage of solids), on request impellers or housing parts of RCH-1000 HMPE (high Modulus Polyethylene) can be supplied. For extremely corrosive mixtures at higher temperatures even a fully PTFE centrifugal pump is possible although the centrifugal pump shaft is not in direct contact with the liquid, it is protected by a replaceable plastic shaft sleeve. The gaskets are standard made of EPDM but may be ordered in Viton or Viton/ PTFE-covered. |

MECHANICAL SEALThe most critical part of a centrifugal centrifugal pump is without any doubt the shaft seal. For that reason high care was given to the development of this part. ARBO produces a single, by the medium flushed, rotating shaft seal. In the liquid zone, there are exclusively high performance plastics or silicon carbide parts. The pressure element ensures the correct shaft sealing and is located outside the liquid zone. It is entirely coated with plastic or made of Hastelloy for maximum durability. The static seal ring is mounted flexible in order to compensate for eventual pressure waves. Optional, the seal box can be provided with a connection for electronic seal damage detection. There is a variety of seal options for system pressures depending on type of 1.5 – 10 Bar. |

|

|

MOTORSAll motors are according NEN-EN-IEC 10072-1 DIN 42673 NEN 3321 standard, 2-, 4- or 6-pole for 230/400 V (up to 2.2 kW) or 400/690 V/ 50 or 60 Hz, IP55, ISO class F. Other protection classes against dust and or humidity on request.PAINT SYSTEMThese centrifugal pumps are often used in corrosive environments. Therefore all metallic parts are coated according NEN-EN-ISO 12944-5 category C3 suitable for outdoor installation. Other painting categories and colours on request.DRY RUNNINGObviously, no fluid centrifugal pump was designed to run without liquid. Still, in practice this may occur sometimes. Thanks to the smart seal design, dry running will cause limited damage only. The shaft seal and sleeve only will get overheated after some minutes and those can be replaced in a very simple way. The relatively expensive impeller and the other housing parts will remain intact!SELF PRIMING CONFIGURATIONCentrifugal centrifugal pumps are normal priming. This means that the installation needs to be in such a way that the suction is flooded. Self priming capabilities can be created.

|

SHORT LEAD TIMESThe ARBO centrifugal pumps feature a high degree of standardization. Thanks to the modular construction and a extensive stock of parts, your specific centrifugal pump may be assembled relatively fast.STANDARD MATERIALS OF CONSTRUCTIONPolypropylene (PP)High Modulus Polyethylene (HMPE) Polyvinylidenfluoride (PVDF) Polytetrafluorethene (PTFE) PP/PVDF/PE-EL = conductive plastics for ATEX-applications  |

MAINTENANCEThanks to the back pull-out system, there is no need to loosen the suction- and discharge piping. The maintenance is reduced to cleaning regularly and the replacement of shaft seal and motor bearings. at normal use, the life time of 30000 operating hours is no exception. Thanks to this, the centrifugal pump is practically maintenance free!All around, a multipurpose centrifugal pump that, together with the variety of options, offers a solution for many applications up to 140°C.

|

More information about the chemical centrifugal pumps and our company, watch the video below:

Want to know more about chemical centrifugal pump?

More information and advice on which centrifugal pump is the most appropriate for your organisation?

Please contact us.

The ARBO single seal TGSI can be executed in double flushed execution at an very attractive price. Besides superior ARBO seals alternatively normalized seals can

The ARBO single seal TGSI can be executed in double flushed execution at an very attractive price. Besides superior ARBO seals alternatively normalized seals can