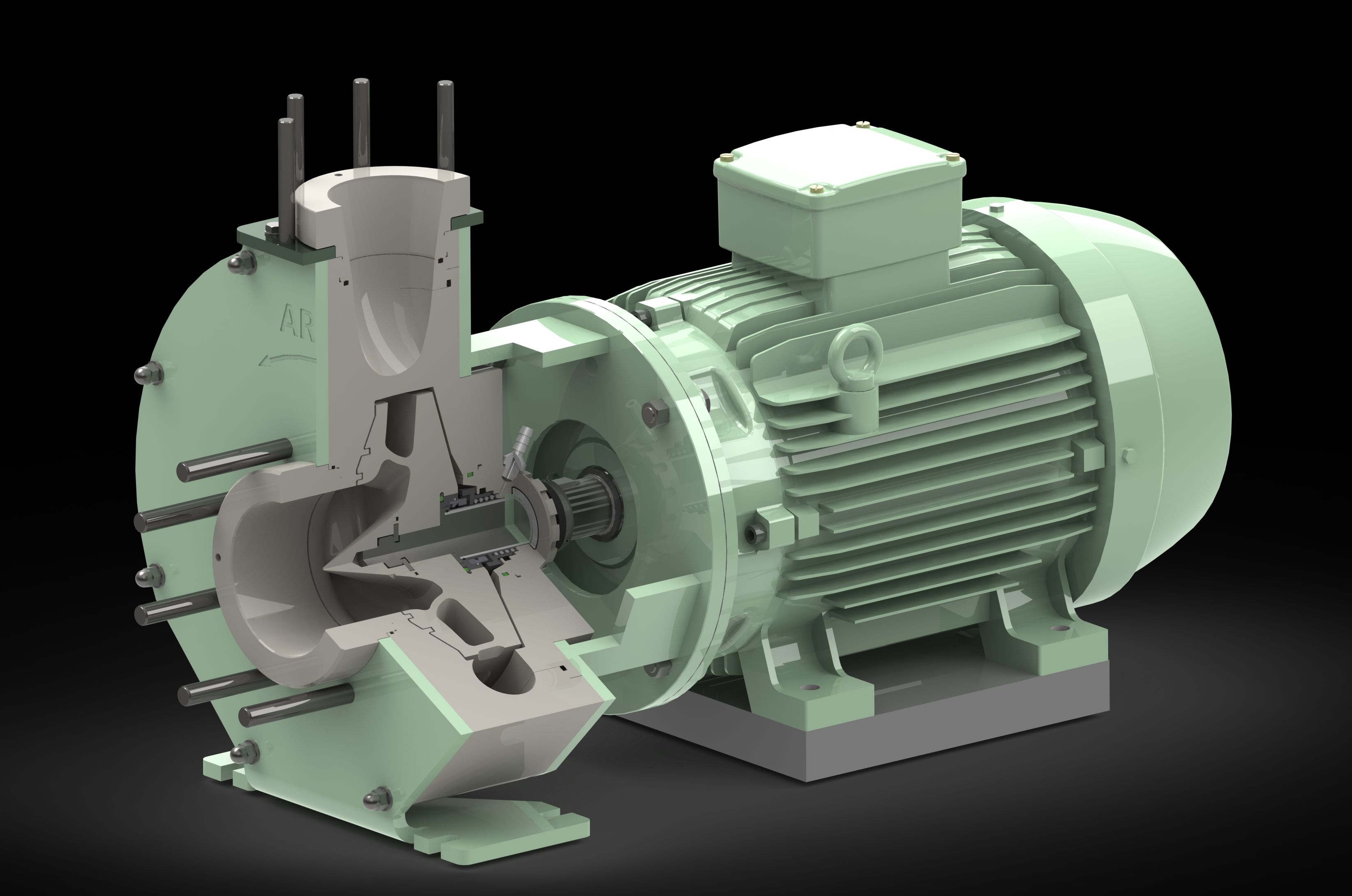

ARBO develops 3 new high efficient plastic centrifugal pumps

The typical application of these pumps is the 24/7 application of chemically polluted liquids or salt water. With this as a starting point for the development, the target is to reach an energy consumption being the lowest of its kind.

The typical application of these pumps is the 24/7 application of chemically polluted liquids or salt water. With this as a starting point for the development, the target is to reach an energy consumption being the lowest of its kind.

These pumps are an interesting alternative for the classical GRP pumps (Polyester in f.i. in seawater applications in the aquarium market segment)

Because of the form stability of glass fiber, narrow tolerances can be achieved in order to obtain a reasonable efficiency. ARBO produces, because of its chemical resistance and durability, centrifugal pumps in thermoplastics.

The limitation of this type of plastic is the ability to deform under the influence of temperature, but this can be compensated by using larger tolerances which again affects the efficiency. Thermoplastics however offer, next to superior chemical resistance, a number of advantages compared to GRP- and metal pumps. Such as the sound dampening effect, wear resistance and material purity due to the lack of resins.

In order to obtain the highest efficiency, ARBO develops and programs impellers with double curved impeller blades. With this feature the efficiency of the pump is achieved by its nearly perfect hydraulic form and not by its narrow tolerances. The advantage of somewhat larger tolerances is the ability of being practically non-sensitive to solids, resulting in less wear and a constant energy consumption over the entire pump life.